Inside or outside? About the wheel’s beadlock design: Which is better for you?

Wheel beadlock function, in fact, is the tire beadlock ring, generally in off-road conditions generated by the special requirements, certainly, it also good work on the road, but the road driving case because the car tire pressure is relatively high (cold tire pressure is generally 2.2bar or more, high-speed will be higher), so generally don’t need this feature, and non beadlock can also make the structure of the wheel design simplified, weight will be lighter, play a role in reducing the quality of the vehicle spring, This is of great practical significance for improving the economy and handling of lightweight non-off-road.

Generally,the beadlock design will only be applied in offroad activities, there is beadlock or not has become an important hardware standard of the wheel offroad capability. In the past hundred years of rapid development of automotive technology, the improvement of hardware has become the sway and guide the human driving skills, just like the SMG technology, overnight will be a lot of people hard to practice for many years of HEEL&TOE technology eliminated, and led a new technology style of the road. The wheel beadlock design greatly improves the wheel’s ability to prevent escape under low tire pressure, thus allowing the wheel’s offroad and relief capabilities to be greatly crossed.

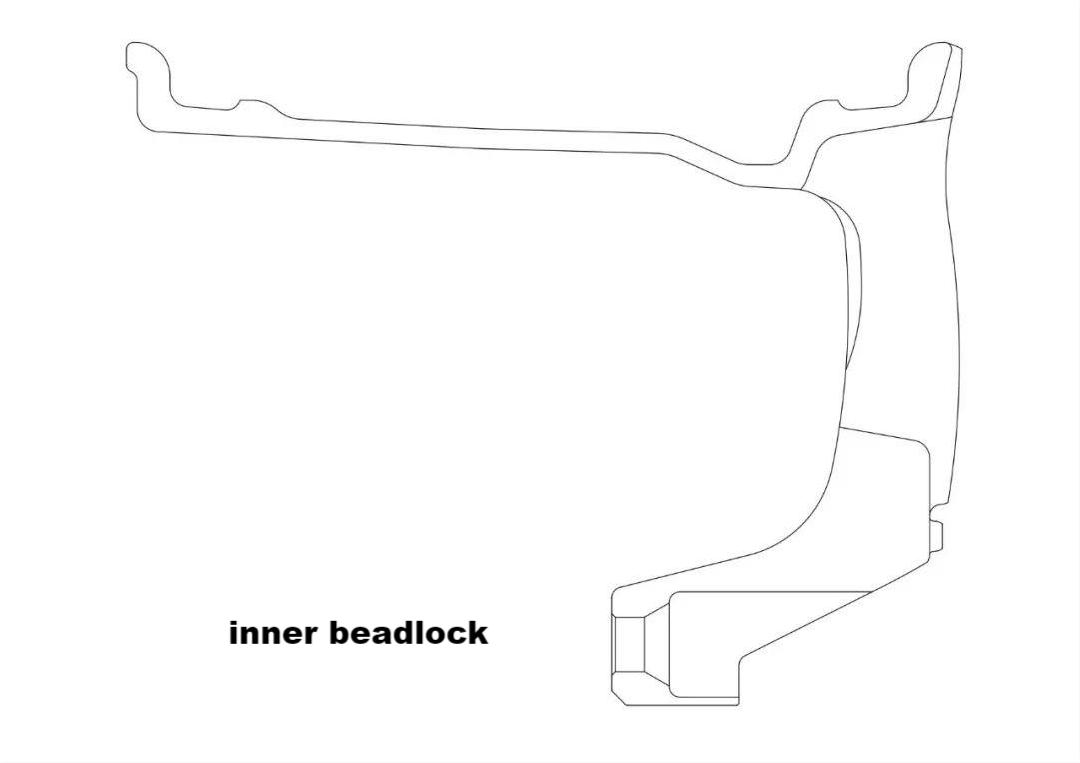

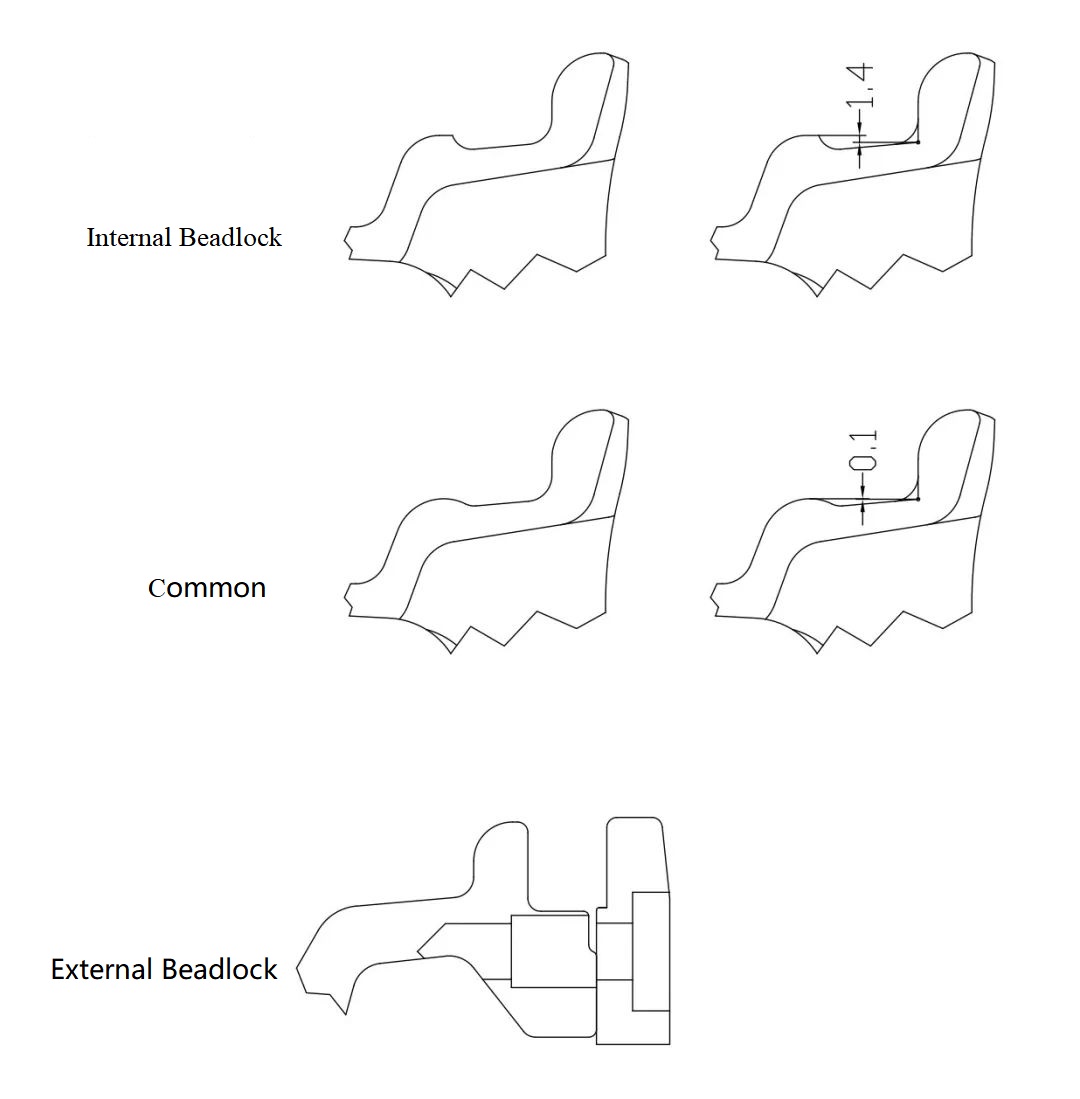

The beadlock of the wheel is roughly divided into two types: the common beadlock and the extreme beadlock, the corresponding combination of the product is the difference between the internal beadlock and the outer beadlock;

Features of internal beadlock:

Easy to install, cost-effective

The biggest advantage of the inner beadlock is that it is installed and ordinary wheels installation method is exactly the same, the difference is that the internal beadlock than ordinary rim more than an anti-off card slot, generally speaking, the width and depth of this card slot is just can be put into the tire tire mouth, we know that the tire tire is very high fastening degree, so as long as it is stuck in place, the tire’s anti-escape ability can be greatly improved. The internal beadlock wheel can be easily installed in the normal way of installing tires, and nothing else needs special means to easily handle everything

The tightness of the internal beadlock wheel card slot;

Due to the design characteristics of the internal beadlock product, its anti-release capability comes from the card slot rather than otherwise, so after the tire installation, the hub itself does not cause damage to the tire wall – whether it is normal tire pressure, low tire pressure or very low tire pressure, because the tab is not completely locked tire wall, in extreme cases, it allows tires and wheels to have relative sliding, but does not easily cause the problem of lapping.

This means that the internal beadlock theory does not completely prevent the occurrence of dislocation behavior, but with proper use, even at very low tire pressure (below 0.5bar) off the ring is completely completely no problem.

The range of applications for internal beadlock

Design-manufactured internal beadlock rings are adequate for our daily requirements, which includes complex road conditions such as off-road-crossing-crossing-desert-Gobi-drying beds-swamps for civilian-grade vehicles. Because civilian-grade vehicle crossing is neither strong nor difficult beyond the high many levels of off-road rally situation. In the four-wheel drive group cross-country rally, whether it is A.S.O’s dakar or FIA FIA or CAMF CAM’s race, the vast majority of the application in these races are internal beadlock wheels, and the fact of the race also proves that as long as the product meets the technical requirements, the internal defense lap in dealing with these conditions without any problems.

The scene where the internal defense can’t cope

The internal beadlock because of structural characteristics, so that it does not have the ability to completely 100% lock the tire wall

Features of external defense:

Using the tire wall ring to lock the tire completely on the hub will not cause displacement and loosening in any case, and it is for this reason that it is very time-consuming and laborious to install, without the use of power tools to fit it you must have Hulk arm, and because of this construction, it is usually relatively heavy.

The external beadlock wheels must be installed with care to the torque of the power tool, as its fixed screws are generally high-strength, mostly class 12.9 products, so be careful not to break the screws with excessive torque.

Application of external beadlock

External beadlock is generally used in more special off-road environment, such as rock climbing and rainforest, but rainforest vehicles generally require the overall weight of the vehicle is relatively light, power is not big, driving distance is also very short, so this requirement is not high, so the use of climbing situation is the most typical.

Climbing because of the environmental problems to face, it is generally not the size of the wheels, but the tire diameter is very large, generally 37-40 inches or so, which makes it have a very thick tire wall;

What’s more, this thick tire wall can provide a great ground area under low tire pressure, whether it is the arc surface of the rock or the vertical surface of the cliff, it can provide much more than the normal tire pressure of the ground area, which gives the climbing car through the seemingly impossible mountain, rock ability, and this ability, the outer anti-removal wheels become indispensable.

Other applications for external beadlock wheels: rear-drive vehicles in off-road rally

In long-distance off-road rally races, only one type of car uses an external rear-wheeled high-powered vehicle, typically buggy and trophy turck; their main features are rear-drive horsepower; and the power is not generally large, but very large, especially the trophy truck, which is usually more than 7,800 horsepower. Such a large power if running on hard road gas is good, if it is soft terrain, such as the most typical desert, that low tire pressure of the violent action can easily lead to tire off-lap, so it needs external defense off-loop to tighten the installation. Of course, corresponding to their equipment of the side wall of the tire anti-tear, anti-twisting and anti-piercing ability are particularly strong, support is also good, and has a very good anti-twisting ability, will not be easily removed from the outer defense wheels to tear the tire wall.

The range of applications for external beadlock

External beadlock wheels in general use, that is, normal tire pressure use is no problem, but generally speaking, the wheels are based on export products, so most of the specifications of the width is large, generally starting is 8.5JJ up, 9JJ are of general specification, and these least 17-inch wheels are mounted on American rock climbers with tire widths above 12.5 inches, or at least 305mm, and large hub widths can cause tires to grind and tire walls to protrude. These are all downsides and require more attention when modifying.

Internal and external beadlock: Which is better suited for everyday

In fact, as long as we have the product characteristics and attention points mentioned earlier, the daily use of the two wheels is no problem; but when we modify, we should also pay more attention to the product style and model style, modification and use of the type of matching and coordination;

Another factor can not be ignored, is the external defense off-loop because of its construction problems, its cost will be relatively high;

Certainly, in addition to the question of personal taste, “My car,my life” is also the truth;

You’re right about everything.

Post time: Jun-18-2021