forging ahead in technology

OUR FACTORY

After years of research and development, Rayone Wheels is proud to be one of the Top 10 wheels factory in the China to produce casting and forged wheels completely in-house. Headquartered in Fuzhou, Jiangxi Province, Rayone's state-of-the-art, JWL&VIA-certified facility features a comprehensive range of brand new machinery.

read more

-

Machine Department

Rayone Wheel uses 12 new CNC machines to manufacture the wheels. And milling machines with high rigidity and spindle speeds reduce cycle times and produce smoother finishes. We can do a variety of complex processes such as turning, machine face, diamond cutting lip, milling window and bolt pattern etc.read more

Car

read more

Luxury Car

read more -

Hand Coating Department

The Hand Prep Department is responsible for prepping the wheel for its final surface finish. Wheels with brushed or polished finishes undergo an additional amount of hand prep, creating a very artisanal look that can only come from an educated hand.read more

DIM SERIES

One of our most iconic series to date. The DIM Series brings back classic wheel styling that will be great for a motorsport, stance, or drift look.read more

THE DIM SERIES

One of our most iconic series to date. The DIM Series brings back classic wheel styling that will be great for a motorsport, stance, or drift look.read more -

Finish Department

Rayone's production facilities include a range of finishing options such as ceramic polishing, hand brushing and powder coating. Custom 20 finish available and red/blue undercut finish, hyper finish and Bronze coating finish, Rayone has complete control over the finished product, guaranteeing exceptional quality and precision in every wheel that leaves the factory.read more

THE DIM SERIES

One of our most iconic series to date. The DIM Series brings back classic wheel styling that will be great for a motorsport, stance, or drift look.read more

620B

With motorsport in mind, the 620B brings back a Heritage feel with modern design techniques. Offered in a vary of sizes and bolt patterns the CR1 also covers "Big Brake" compatibility.read more

Design

Many alloy wheels factory utilize the simplest and most common machining techniques to increase production volume. The Rayone wheels, particularly the Rayone Racing series, does not compromise its exclusive and complex features for manufacturing ease.

read more

-

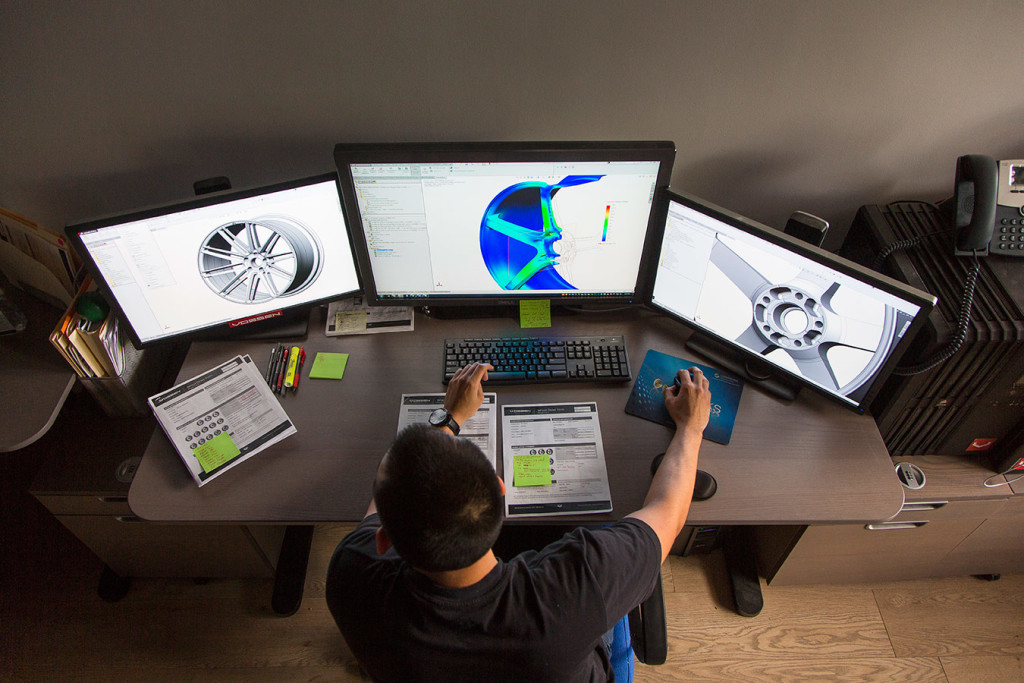

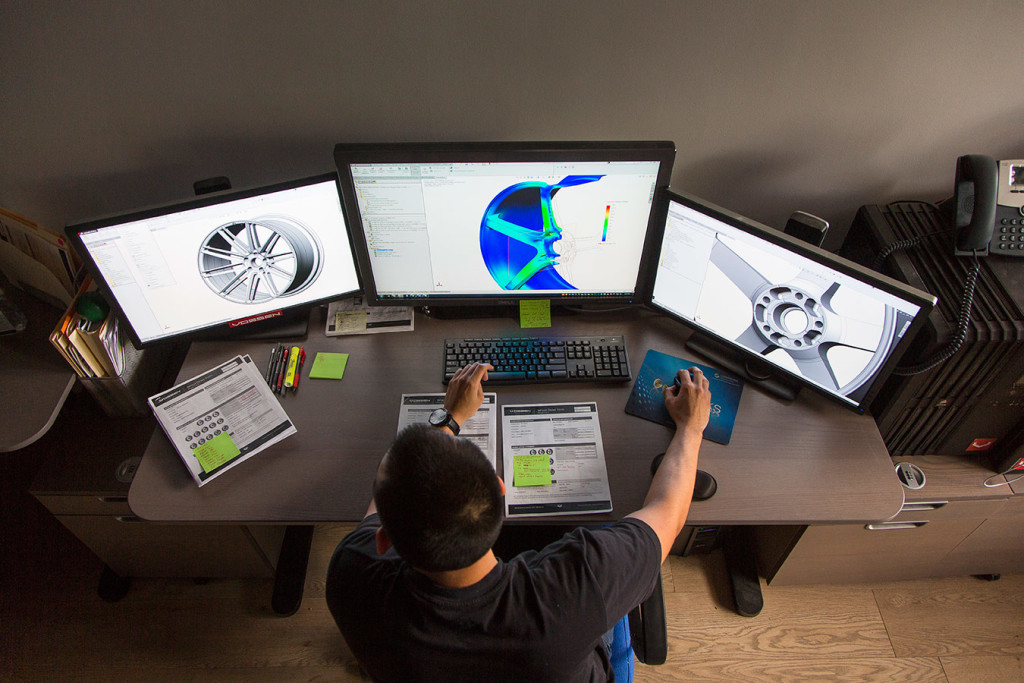

Design Process

Rayone wheels have over 800 iconic molds and support mold opening service. Open mold need 30days and usually the design process begins with identifying the end goal. Gaps in both our product line and the market help guide the direction of new designs. We try to see what’s missing and fill in the blanks from there, typically beginning with a 3D model.read more -

Diamond Cutting Lip

The Diamond cutting face feature of the deep dish wheels, embodying simplistic elegance and purity of design. Without the utmost precision throughout the entire manufacturing process, a like mirror finish from the wheel face would be impossible.read more -

Vehicle Optimized Aesthetics

Every car make and model has different parameters and clearances as well as different general aesthetics. Utilizing our extensive measuring process and Vehicle Tailored Engineering, Rayone wheels are optimized specifically for each vehicle, maximizing concavity and perfecting overall fit.read more

WHEELS SHOW ROOM

Rayone are Top 10 alloy wheels factory in China, have 3 wheels brand, Rayone Wheels, DIM Wheels and KS Wheels, they are well known in Asia and Europe. We have 800 models in our catalog, also keep 15,000pcs in our warehouse each months for all oversea customers choose from.

read more

-

Rayone Racing Wheels Show Room

The Rayone Racing series covers 13-24 inch aftermarket design wheels, from the classic mesh design to the iconic five-spoke design, Rayone wheels is committed to the development and design of new styles, on average, 15-20 different styles of wheels will be launched every year.read more -

DIM Wheels Show Rom

If you see a red and black DIM box in the wheel market in any country, it is undoubtedly from rayone's DIM series. The DIM series is very famous in Asia and South America, and more than 20 new dealers use our DIM cartons of wheels for each months.read more -

KS Wheels Show Room

The KS series is currently available in 8 models, representing different styles and eras. The KS series is a brand new series designed in cooperation with a Japanese wheel company, they have high performance and wheel strength higher than the Japanese JWL standard, nowadays the KS has popularity in Europe and Australia, and has made a splash in the Australian rally.read more

Engineering

Precise fitments are achieved by taking measurements from over 100 different data points around the car. Those measurements lead to CAD models that are tested using Finite Element Analysis (FEA) to ensure JWL and VIA compliance while maximizing concavity. Each wheel is specifically made for each vehicle make and model.

read more

-

Test

Every Rayone wheel design is physically tested in compliance with JWL and VIA standards. Using Finite Element Analysis (FEA) software each wheel undergoes simulated cornering, radial, and impact testing specific to the vehicle.read more -

Measurements

Over 100 measurements are collected from each vehicle, including the weight rating and distribution, to determine each wheel’s minimum material requirement. Exclusive to the Precision Series, the center drop, hub, and mounting surface diameters are specific to the bolt pattern of the vehicle, allowing for further weight reduction.read more -

VEHICLE-TAILORED-ENGINEERING

Rayone’s Vehicle Tailored Engineering ensures that your vehicle will attain its optimal style and performance. Every Precision Series wheel is engineered to be superior to the OEM wheel it is replacing and the ultimate fit is achieved by considering the maximum width, offset, and concavity that the car’s dimensions will allow.read more

WORKSHOP

The monthly production capacity of Rayone wheels reaches 100,000 pieces, with a total of 10 production lines. All wheels go through the dynamic balancing workshop, X-ray workshop, rough workshop, finishing workshop, as well as the painting department, impact test room, and finally to the QC department, where they are tested and qualified before being sold overseas.

read more

-

MATERIAL

Manufacturing the best wheels in the industry begins with nothing but the finest raw materials, made in China. Rayone Racing wheels are made of top grade A356.2 aluminum into a proprietary wheel design. Heat-treated for additional integrity, these racing wheels quality equal to and sometimes greater than the raw materials used by the world’s top OEM automakers.read more -

CNC MILLING

In this phase of production the wheel’s design is revealed while the CNC machines remove as little as 0.02” of material per pass to achieve the utmost precision. An array of exclusive and intricate milled features characterize the Precision Series, while other Rayone Racing series have similar details echoed throughout.read more -

Full customization

Rayone Wheels supports full customization, such as PCD customization, ET customization, CB customization, as well as color process customization services, lettering and logo customization, our minimum order quantity is 120 pieces per design, and the production time is about 40 days.read more

safety monitoring

Every Rayone wheel undergoes a thorough quality control process from casting to completion and passes the most rigorous JWL & VIA wheel tests. Rayone's wheels are guaranteed for three years and are approved by all our dealers.

read more

-

Quality Control

Precision requires consistency and consistency requires control, which is why Rayone meticulously inspects every wheel during every step of the process. Rayone machinists conduct inspections on every wheel to ensure precision before proceeding to the next step. The quality control team confirms every critical dimension according to detailed engineering schematics. Runout, a measurement of a rotating wheel’s roundness, is the most critical measurement. Rayone Racing wheels are checked to confirm that the runout is within tolerance.read more -

Warranty

Every Rayone wheel undergoes a thorough quality control process from casting to completion and passes the most rigorous JWL & VIA wheel tests. Rayone's wheels are guaranteed for three years and are approved by all our dealers.read more -

Fast Production

Rayone Wheels supports full customization, such as PCD customization, ET customization, CB customization, as well as color process customization services, lettering and logo customization, our minimum order quantity is 120 pieces per design, and the production time is about 40 days.read more

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur